About BBM

What is BBM

BBM is the shorter name of Bamboo Biodegradable Material, developed by Leishi company with patents, a new type of biodegradable material which is no plastics, no carcinogenic plasticizer, no fluorescent agent, no pesticide added, heat&frost resistant, compostable, nature decomposable, recyclable. Its products have good tensile strength, waterproof and oil resistant. Certificated by German TUV Rheinland that BBM is biodegradable and it become compost within 12 weeks. BBM has a wide range of uses, can replace conventional plastics to produce a variety of products, such as disposable tableware, film bags, packaging films, 3D printing consumables, etc.

What source of BBM

BBM is sourced from natural bamboo by crushing and grinding, processed by high-precision equipments. Bamboo is everywhere in China, sourced conveniently and stably. It grows prolifically and rapidly in its natural home, it is a highly sustainable plant. BBM with bamboo powder as the main ingredients, is the best choose for biodegradable products.

What are the advantages of BBM

01. biodegradable, compostable

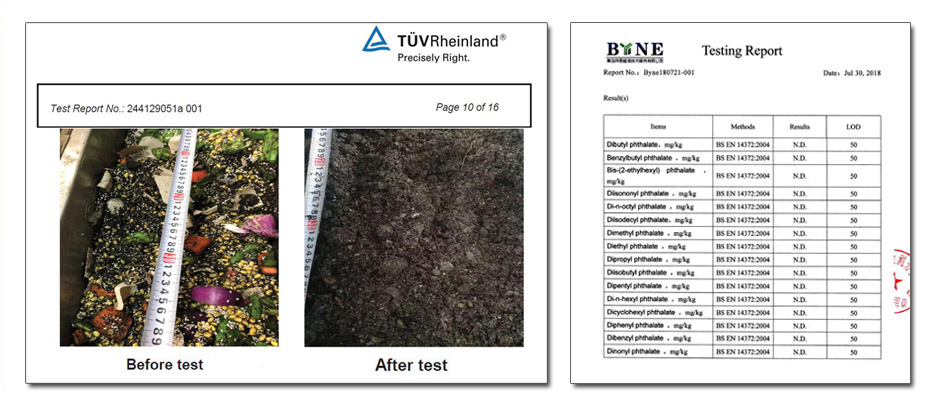

Certificated by German TUV Rheinland that BBM decompose into CO2 and water and turn to excellent compost within 12 weeks oven time. not only in composting condition but also in nature it disintegrates into CO2 and water, so when BBM products buried in the soil, it contributes to soil relaxation and air permeability, preventing soil compaction and promote the growth of plants. it is definitely new environmental-friendly material.

02. Non-plastic/carcinogenic plasticizer/fluorescent agent/pesticide addition

Generally, people refer to PE, PP, PS、PVC、PVE these kind of conventional plastic as plastic, BBM is non-plastic, it is processed by bamboo powder as the main material, high-speed mixing and refining with other fully biodegradable polymers. BBM is 100% biodegradable and eco-friendly, while conventional plastics can’t degrade for hundreds of years and bring terrible pollution to the environment.

What’s more, conventional plastics or many called “biodegradable materials” contains much O-benzene plasticizer which used to make them more softer or stronger, but they're carcinogens which harm people's health seriously.

With big plus of BBM, Certificated by BYEN that BBM contains no any carcinogenic plasticizer, in additon, it is no fluorescent agent and no pesticide added, it’s a green material, more suitable for people's tableware and food packaging.

03. Heat&frost resistant, waterproof and oil resistant, good tensile strength

The reason why biodegradable materials have become a hot topic in the world is not only because of the increasing shortage of energy and the urgent need to solve the problem of plastic pollution, but also because there are still many problems in the application of biodegradable material.

Take PLA or lots of other bio-plastic for example, the products are poor mechanical properties, like the bags that are not strong enough and easy to tear; when in high or low temperature, the products will change shape or become crispy, so they are not a good material to make tableware such as lunch boxes; because of poor plasticity, the products are difficult to make shapes, such as bending straw are unable to meet, etc. To solve these shortcomings, they have to add lots of conventional plastics and plasticizer , in order to make out the good products. However, this is not a fully degradable biomaterial at all, but only a partially degradable plastic or it’s not much different from the conventional plastics.

BBM has solved these problems. Its products are resistant to high temperature and low temperature - 20-100 ℃, waterproof and oil-resistant, with good mechanical flexibility and 100% biodegradation.

04. Available production line is workable, no need to add new facilities or labors, easy process.

No matter what kind of your available machines for conventional plastics or bioplastics, you can use BBM to produce products smoothly, no need to add additional equipments such as crystallizer, no need to increase quantity of workers, it’s higher efficiency, lower cost, high out-put, stable quality and simple process.

05. lower processing temperature, lower cost.

The processing temperature of BBM products is 120-160 degrees, while the conventional plastics require 190-260 degrees, so use BBM for production meets lower temperature and that reduce the production energy consumption and production cost further.

06. Zero wastewater, zero-discharge

Those rejects, nozzle materials, leftovers during the production process, could be smashed and recycled to next production, no waste, reduce energy consumption and lower costs greatly.

What can BBM use to do

|

Shantou Leishi Plastic Technology Co., Ltd. |

Contact us:

www.leishibiobbm.com

sales@leishibiobbm.com

Tel.: +86 754 87296298

Tel : 0754-87296298

Tel : 0754-87296298